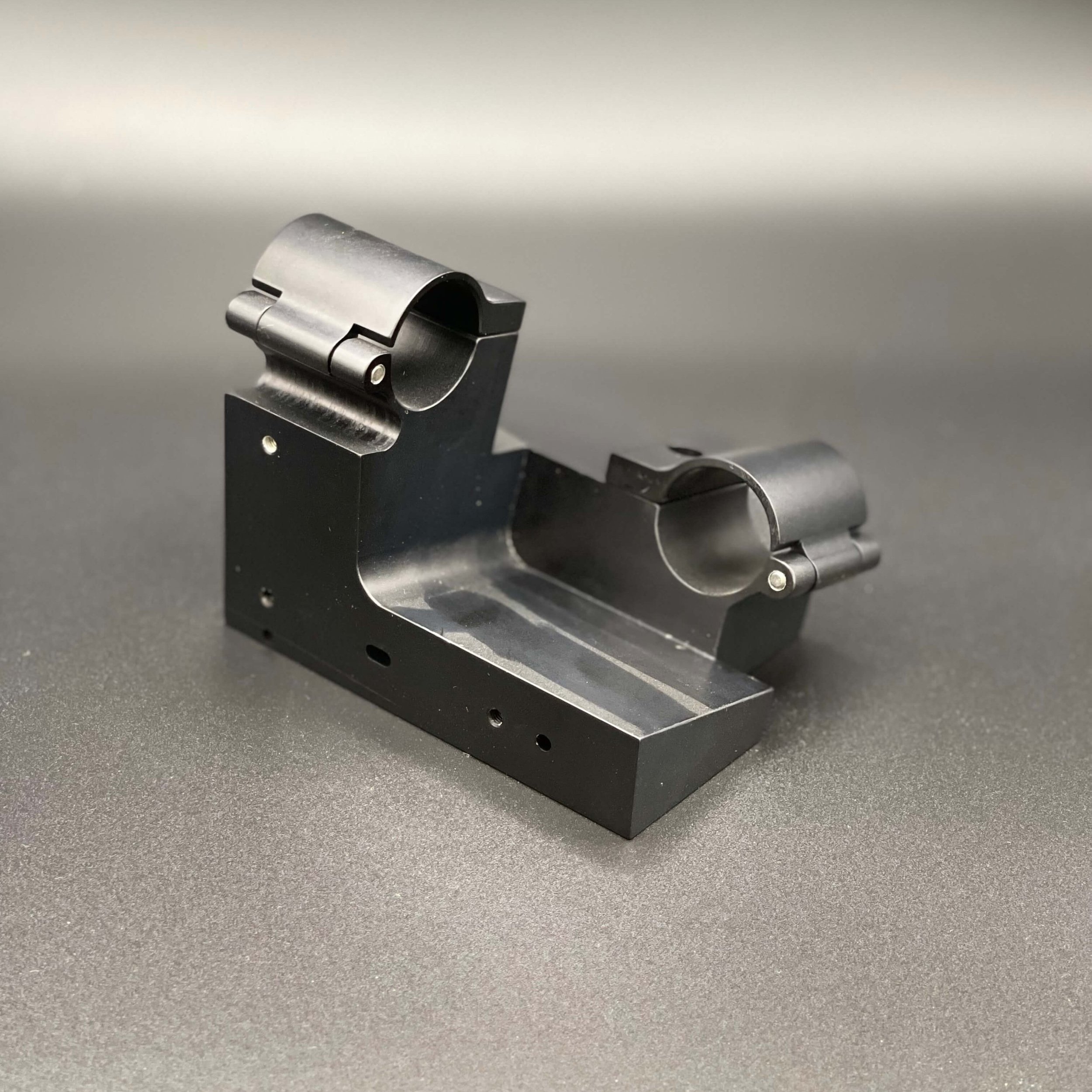

Our New Machines Make Our Prototype Machining Services Even Better

Developing a prototype is a huge undertaking that requires significant time and effort. So when it comes time to manufacture your prototype, you want to feel confident you’ve found the right partner for prototype machining services.

Armstrong Machining is that partner.

We’re dedicated to helping our customers bring their prototypes to life quickly and cost-effectively, which is why we recently invested in not one. . . not two. . . but three new HAAS VF-2YT machines specifically for prototyping and low-volume projects.

Why Did We Invest in New Equipment?

You may know that Armstrong Machining recently underwent strategic improvements under new ownership. And the “new and improved Armstrong Machining” is absolutely committed to continuous improvement. Every decision we make is for the benefit of our customers, whether they come to us for prototype machining services, production, or both.

As part of our continuous improvement efforts, we’re aiming to replace all our older equipment with new state-of-the-art machines that can manufacture prototypes and low-volume parts better and faster.

The result? You get an exceptionally high-quality prototype to test and assess, and you still have plenty of time to iterate before moving on to production.

How Our HAAS VF-2YT Machines Benefit You

Here are some of the ways our customers benefit from our new equipment:

High precision

A rigid and robust machine, the HAAS VF-2YT features a high-power, direct-drive spindle that ensures incredible precision. Plus, one of ours is equipped with a Renishaw probing system capable of probing accurately to 0.002”.

Excellent surface finish

Older models simply can’t compete with our brand new HAAS VF-2YTs when it comes to surface finish quality. If we were to run the same part on an older machine vs. the HAAS VF-2YT, the difference in the surface finish would be clear to the naked eye.

With high-quality spindles and tight X and Y tool paths, these machines can achieve surface finishes down to 16 Ra—ideal for many applications, including parts with vacuum-sealing surfaces.

Impressive speed

The HAAS VF-2YT can make complex parts in a fraction of the time it would take an older machine. With a feed rate of 1,400” per minute on all axes, it can go from tool change to tool change and cut to cut in a matter of seconds.

That’s Not All. . .

Did we mention that we recently bought a fourth new machine, too? We’ve been so happy with the HAAS VF-2YT that we recently purchased a HAAS VF-3YT, which offers all the same benefits as the HAAS VF-2YT—and then some.

It has a larger footprint so that we can machine bigger parts. And it features a side-mount tool changer that automatically freefalls the next tool in the setup, allowing us to reduce cycle times dramatically for parts with multiple tools.

If you want prototype machining services from a shop dedicated to continuously improving, request a quote from Armstrong Machining today!