Armstrong Machining Blog

How to Find a CNC Machine Shop

Finding the right CNC machine shop can be a daunting task. With so many options available, it's easy to feel overwhelmed and unsure of where to start. The most important factor when choosing a shop is that they are capable of completing the work you need done, but the thing that sets some shops apart is the way they conduct their business.

Our New Machines Make Our Prototype Machining Services Even Better

Developing a prototype is a huge undertaking that requires significant time and effort. So when it comes time to manufacture your prototype, you want to feel confident you’ve found the right partner for prototype machining services.

How to Reduce Back and Forth with Your Precision Machine Shop

At Armstrong Machining, we’re committed to manufacturing high-quality parts at our quick turn machine shop. We’ll always conduct our due diligence to catch any issues or discrepancies in a customer’s design before precision machining begins. And we’re happy to have a conversation with you to understand your intentions and determine the best path forward.

Your Go-To Shop for Parts with Vacuum-Sealing Surfaces

When the surface of a mounting plate mates with an o-ring, it’s imperative to achieve a reliable vacuum seal, and that’s only possible if the mounting plate has a critical, greaseless, vacuum-sealing surface.

Tool Suppliers: the Secret Sauce for Our Precision Machine Shop

At Armstrong Machining, we prioritize customer satisfaction and go the extra mile to ensure you get the most value for your precision machined parts. Sometimes, that means putting our egos aside and calling in outside experts to advise on a particular situation.

4 Industry 4.0 Technologies at Armstrong Machining

The Fourth Industrial Revolution—also known as Industry 4.0—is here and has brought with it incredible advancements in manufacturing technology. Precision machine shops now have ample opportunities to increase efficiency and productivity by leveraging technological innovations. But change isn’t always easy—or affordable—and as a result, many shops have been slow to embrace these solutions.

What It Means to Be a Customer-Centric Machine Shop

The manufacturing industry is rife with challenges right now, including supply chain disruptions and labor shortages exacerbated by the COVID-19 pandemic. Now more than ever, customers need a machine shop they can rely on for smooth and efficient manufacturing. When the customer-manufacturer relationship is strong, it’s easier to navigate the complexities of this industry and overcome challenges—together.

How to Avoid Confusion with Your Machine Shop and Get Your Parts Faster

Time is the most valuable commodity in manufacturing. Every second matters. The longer a machine shop spends on your project, the longer it takes for you to get the parts you need. If you want to speed up the manufacturing process, we have a simple solution for you: Be up front and specific about your requirements from the beginning.

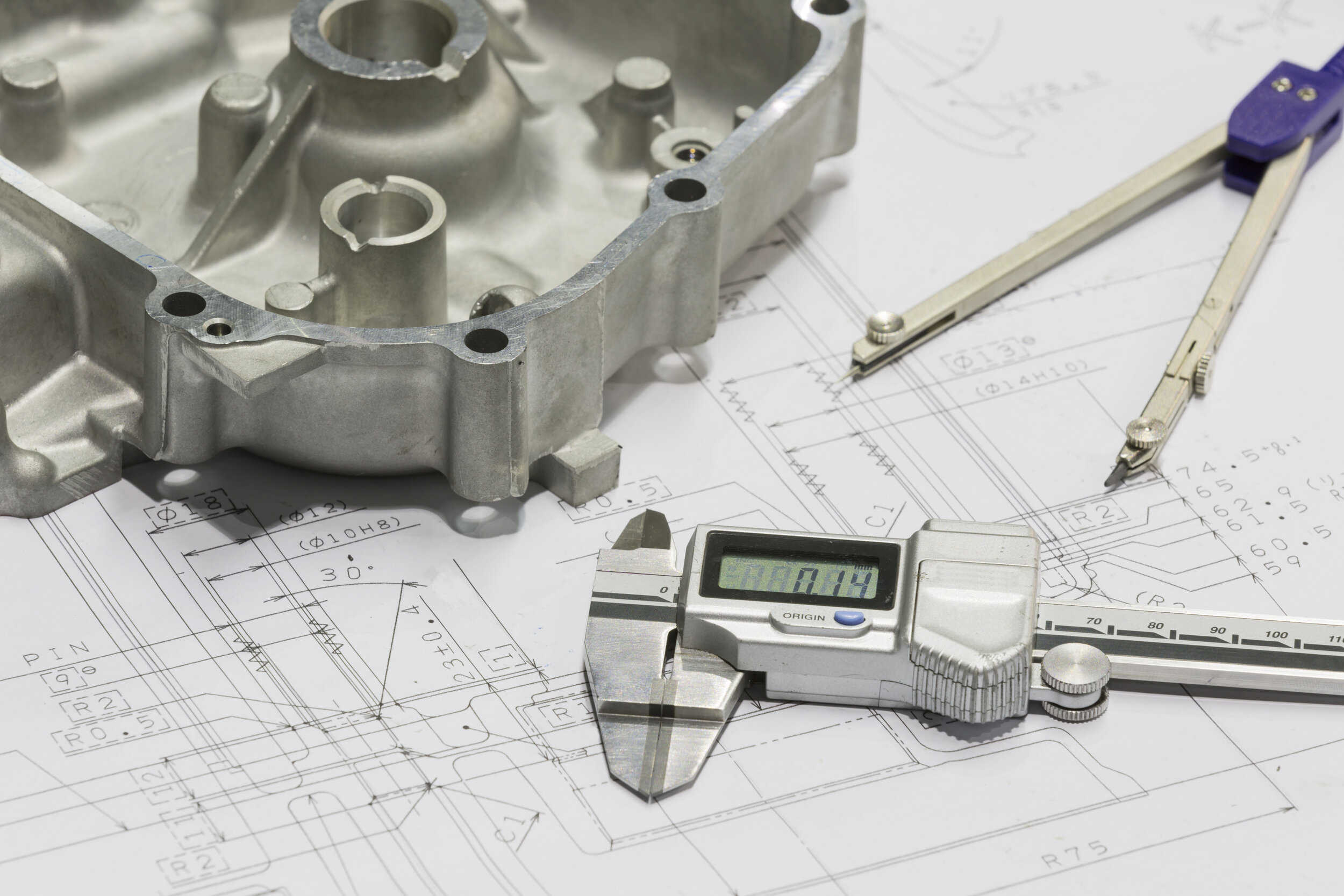

Why Use the Same Precision Machine Shop for Prototyping and Low-Volume Production

Prototyping is an involved process that requires intensive upfront work and problem-solving. To get a high-quality prototype with superior functionality, you need a dedicated prototype shop with the right capabilities and expertise.

Optimize Your Machining Timeline for Rapid Prototype Machining Services

Are slow lead times your number one manufacturing concern right now? Trust us, you’re not alone! The COVID-19 pandemic catapulted global supply chains into a state of total disarray, wreaking havoc across the entire manufacturing industry.

The New and Improved Armstrong Machining

We’re proud to tell you all about the new and improved Armstrong Machining, formerly known as Armstrong Machining Company. Originally owned by Ray Armstrong, the shop you know and love has recently undergone strategic improvements under new owner Scott Garron.

Are You Overengineering Your Prototype?

Are you overengineering your prototype? If the answer is “yes,” chances are you’re overspending, too. Prototyping is by nature an iterative process. It’s an opportunity to test, scrap, and redesign a part until you get it right for production.