Your Go-To Shop for Parts with Vacuum-Sealing Surfaces

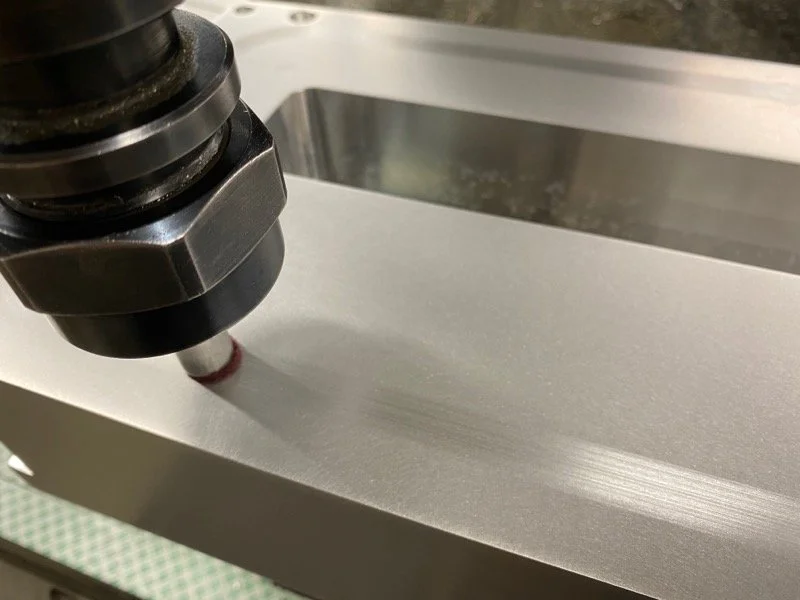

When the surface of a mounting plate mates with an o-ring, it’s imperative to achieve a reliable vacuum seal, and that’s only possible if the mounting plate has a critical, greaseless, vacuum-sealing surface.

Our quick-turn machine shop specializes in machining these surfaces. We’re continuously improving our process to maximize efficiency while ensuring pristine vacuum-sealing surfaces for our customers.

What Is a Critical, Greaseless, Vacuum-Sealing Surface?

If you have parts that will be in a high-pressure application and need to seal together tightly, a critical, greaseless, vacuum-sealing surface can help guarantee a secure fit.

Many different parts require vacuum-sealing surfaces, and the part materials can vary. At our precision machine shop, we primarily machine mounting plates for customers in the semiconductor and medical industries using aluminum and stainless steel.

Typically, these parts are stacked together inside of a machine. The vacuum-sealing surface of one part must mate against the o-ring on a separate part.

Continuously Improving Our Technique

At Armstrong Machining, we’re committed to continuously improving our internal processes.

We’ve been machining parts with vacuum-sealing surfaces for many years now, and we’ve worked hard to master our technique. We’re proud to guarantee quality and efficiency for each of these parts we make:

Quality. We consistently achieve surface finishes down to 4 Ra. While some shops hand-finish vacuum-sealing surfaces, we program our CNC milling machines to run a Scotch-Brite pad over the surface, providing a single-direction grain finish that consistently meets customers’ specifications.

Efficiency. We’ve streamlined our process to be as efficient as possible, eliminating bottlenecks that traditionally occur when multiple departments work on parts with vacuum-sealing surfaces. We create these parts faster than ever now and are always looking for the next opportunity to improve our approach.

If you need a mounting plate or another part with a critical, greaseless, vacuum-sealing surface, trust our quick-turn machine shop to deliver. We enjoy making these parts and are ready to apply our expert approach to your next project. Request a quote to work with us!